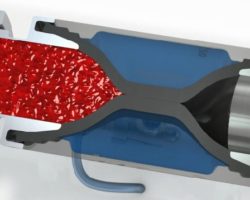

A Pinch Valve is made up of only 3 parts: The body, end connections, and rubber sleeve. The pinch valve sleeves (also known as a rubber membrane, bladder, hose, tube, diaphragm, collar etc), are the most crucial part of the Pinch Valve, and are available in a wide range of different rubber materials.

Depending on your pinch valve application, AKO can advise you on the best suited sleeve to ensure your application works to its full potential.