AKO UK Pressure Relief valves are becoming more and more popular for protecting pumps and motors from damage.

As approved under the Framework agreement with Aquagas AVK.

AKO UK have launched their new EX Pinch Valve for use in potentially explosive environments, with sizes ranging from 15mm to 200mm.

By complying with EX, named after the French “ATmosphere EXplosible”, AKO UK are starting to realise the potential in new markets.

The AKO EX valve is intended for use in potentially Explosive Zones 1/21 or 2/22. The only visible differences on the actual valve are the lock teeth washers and the earth connection. The washers are used with the flange bolts to give full contact with the aluminium body through the paint, this ensures if required, electrical current can pass safely though the Pinch Valve. The earth connection is located on one of the flanges or screwed ends of the valve.

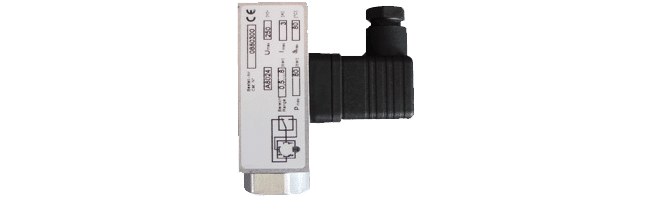

The optional Norgren pressure switches are also fully EX Approved.

The AKO Pressure Relief Valve is fitted onto a bypass line of a pump. The valve is then charged with air and set closed at the pressure it is required to relieve at. If the associated pump becomes clogged or blocked, causing the line pressure to exceed the pressure at which the valve is set closed at, it will open allowing the product to bypass the pump equalizing the pressure until the blockage is cleared. When the blockage is cleared the valve will reset itself in it’s ‘closed’ position to the original set pressure.

When a bursting disc has ‘burst’ it has to be manually reset, while a spring valve often has to be stripped and cleaned. The AKO Pressure Relief Valve resets itself, which is also a huge advantage as most pressure relief valves are always used on remote sites.

Conventional spring-operated globe-type valves have always been popular for most pressure relief duties, but in some applications the spring can easily become clogged with ‘difficult’ products being pumped; and the result is a pressure-relief bypass line that constantly fails to close properly.

Experience has shown that spring-operated relief valves require an operational tolerance band which is significantly wider than that required by the AKO Pressure Relief Valve. Consequently, in some installations the higher risk of damaging a pump or its drive motor because the spring fails to act at the correct pressure, this leads to the use of the AKO Pressure Relief Valve, which are considerably more reliable in their operational threshold.

At a sewerage treatment plant in Milton Keynes, Four 150mm progressive cavity pumps are used to move sludge between treatment tanks during the water-recovery process. Each pump is equipped with a simple bypass controlled by an AKO Pressure Relief Valve. Kept normally-closed by an air pressure of 6 bar, the pinch valves are only forced open if the sludge pressure in the line builds up either by someone closing a downstream valve, or due to a blockage caused by the heavy solids content of the sludge. Once the line pressure exceeds 6 bar, the sludge effectively forces open the pinch valve by back-pressure. Once open, the pinch valve allows sludge to flow into the bypass, back to the suction end of the line-thus equalising the pressure and protecting the pump.

Once charged with air, the AKO Pressure Relief Valve does not need constant air supply. Normally a foot pump is supplied, another advantage when the valves are being used in remote locations when compressed air is not available.

The valves can also be fitted with EX approved IP65 Pressure Switches. It is set so it will send a rising signal when the valve is relieving, or a falling signal if there is a problem with the valve. The electrical signal can be sent to a local starter or PLC Control to stop the pump or open/close other valves on the system until the problem is rectified. An alarm or telephone alarm can also be sent to alert operators that maintenance is required.

Other important advantages of the AKO Pressure Relief Valve include: clear and true bore meaning no blockages or friction, no mechanical parts to get clogged or blocked, single body casting meaning no chance of leaks, all valves are fully tested with unique tracking number, easy and low cost maintenance, quick and efficient deliveries from the largest UK Pinch/Pressure Relief Valve stock and finally full technical back up and valve maintenance in house or on site.

The AKO Pressure Relief Valve is proving to be the best and most cost effective solution to protect pumps and motors from over pressure and damage.