Stainless steel Pinch Valves provide precise and effective control involving opening and closing operations. The easy replacement of the elastomer/rubber sleeve and easy installation makes stainless steel Pinch Valves a preferred choice in industries where cost-effective and simple design solutions are required.

Among the different types available today, one of the widely used is stainless steel pinch valves. The reason behind their popularity is that they are robust and suitable for use with all types of fluids and solids, especially the ones that are corrosive and abrasive.

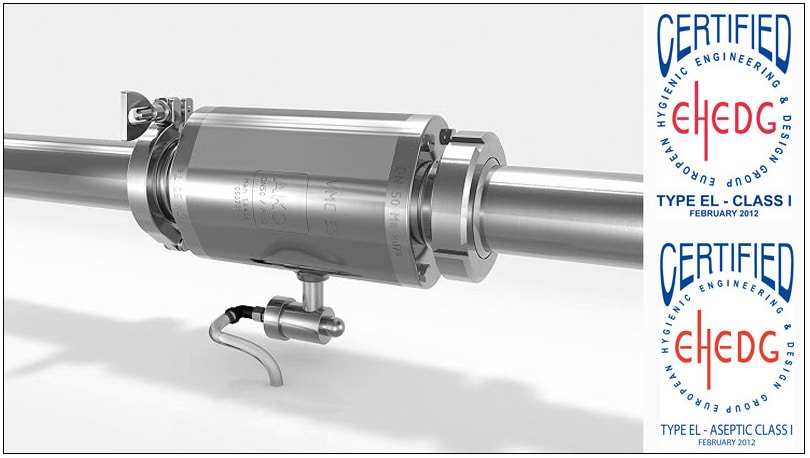

AKO offer two types of stainless steel pinch valves: The VMC type, for food & beverage industries and high temperature abrasive applications. And the VMCE type, for aseptic and hygienic applications – see more below.