“The ball valves we previously used suffered from scoring across the ball surface due to the abrasive sand particles (0.6-1.0mm). This allowed water to pass through the valve when it was closed, but not the sand or cement in the mix. When the valve for cement slurry was re-opened, a pellet of mix with a reduced water content from directly behind the valve would then lead the flow along the delivery hose until it got to the spray head nozzle. Being too dense and stiff to pass through the nozzle (5mm) this small portion of hardened mix would block the spray head and cause the hose to blow off under the pump pressure, with consequences you can probably imagine.”

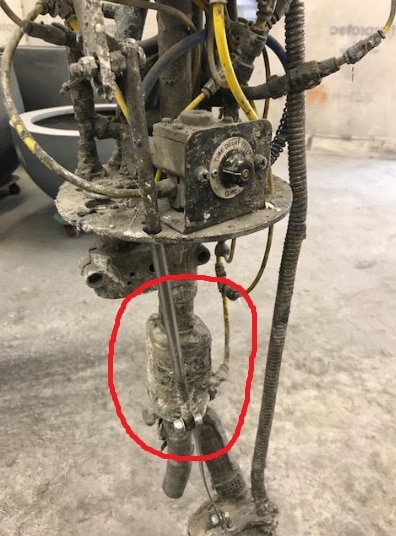

The company have currently been using the AKO Pinch Valve for cement slurry for 2 years. The air actuated ball valves that they were previously using required frequent replacement due to wear on the moving surfaces.

“We love our pinch valve for cement slurry – but we had to introduce a pneumatic timer in order to allow the helical reinforced supply hose we use to unload to a pressure within the working values of the pinch valve i.e. max pressure differential. The valve then closes, but following a 7 second delay after the pump is switched off. Because the pump we use is peristaltic where a rotary shoe squeezes the pump tube and forces material out, it delivers material in a series of pulses. For spray consistency, the gun requires an even supply of material, so the helical hose stretches along it’s length and accommodates the increase in pressure on the out stroke, then releases the pressure to maintain flow to the spray head while the pump briefly dwells prior to the next pulse.”

Testimonial from Richard, the Valve User on site: