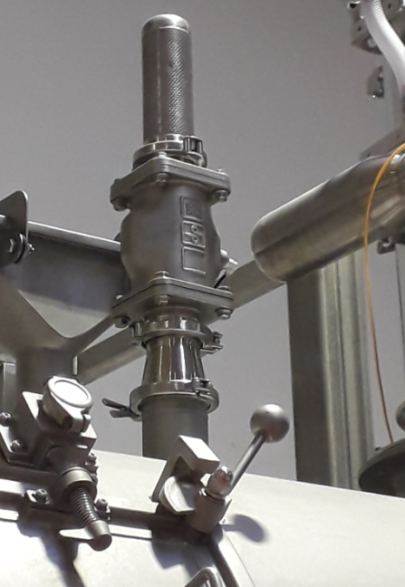

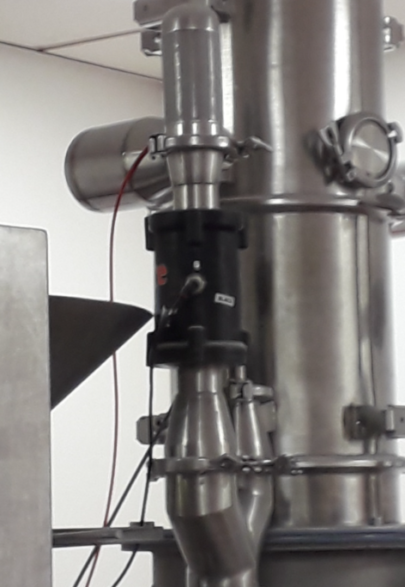

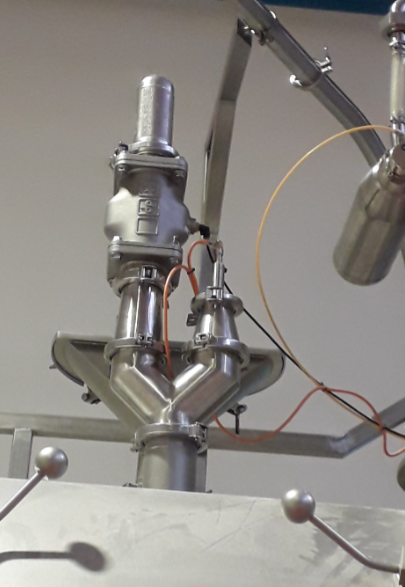

Positioned at the top of the mixing machines, just below a breathing filter, the food ingredients manufacturing company currently have four Pinch Valves in use on their site. There is no media passing through the valves, instead, the valves are closed during the vacuum process and then reopened during the mixing cycle. This process involves up to 80 cycles per day.

How does the Vacuum process work?

The company vacuum their ingredients through a sieve and into a mixing machine for blending. Whilst vacuuming the ingredients to their machines, the Pinch Valves are closed to create a seal at the breathing filter. Once the vacuum process has completed, the Pinch Valve is then in an open state to allow for the machine to blend the ingredients together as air passes through the breathing filter above the Pinch Valve. The amount of vacuum being used is 2.5 bar.