A global leader in adhesive and sealant solutions, operates an advanced cementitious powder plant in the UK. The facility handles a variety of powder and sand-based materials essential for the production of construction products. Efficient and reliable flow control is critical to maintaining the high standards of product consistency and plant uptime that Bostik is known for.

Reliability That Lasts: 26 Years of Smooth Powder Flow with AKO Pinch Valves

Challenge

Within the end user’s cementitious powder plant, fine powders and sand are transferred from silos to mixers through a network of pipelines. The abrasive nature of the materials, combined with the high frequency of daily operation, places significant demands on any flow control equipment used in the process.

Key requirements for the application included:

-

Handling abrasive materials: Cementitious powders and sand can cause wear in valves and fittings.

-

Frequent operation: Valves perform between 30–40 open/close cycles per day.

-

Low pressure system: Material flows at 1 bar line pressure and ambient temperature.

-

Reliability: Valves must maintain consistent performance with minimal maintenance.

-

Compatibility with multiple orientations: Valves installed in both vertical and horizontal pipework.

The company required a durable valve solution capable of consistent shut-off performance under these demanding conditions.

Solution: AKO UK Pinch Valves

To meet these operational challenges, the company selected Pinch Valves supplied by AKO UK Ltd, a leading manufacturer of air-operated pinch valves for handling powders, granules, and slurries.

Over the past 26 years, the company has installed and operated 30+ AKO Pinch Valves across its cementitious powder plant. These valves are primarily used to control the transfer of powders and sands from silos to mixers — opening when product is required and closing once transfer is complete.

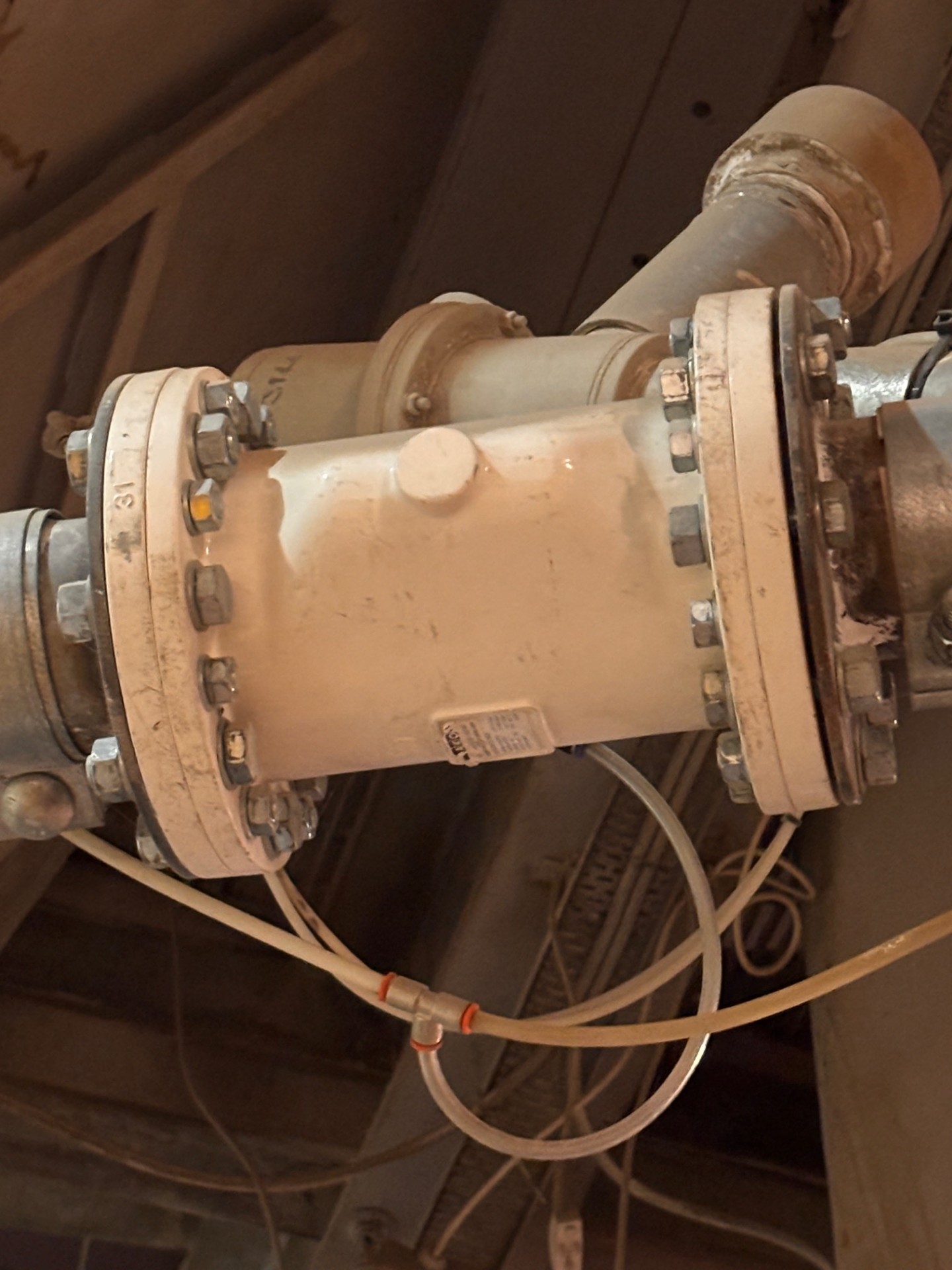

Pinch Valves used within this application – VF100.03X.31.30LA & VF080.03X.31.30LA

VF model, air operated, aluminium body, aluminium flanges PN10/16 with mild steel bushing contact parts, natural rubber sleeve.

Technical Configuration

-

Valve Type: AKO Air-Operated Pinch Valves

-

Number of Valves on Site: 30+

-

Media: Cementitious powder and sand

-

Flow Pressure: 1 bar

-

Operating Temperature: Ambient

-

Air Pressure to Close: Originally 7 bar (advised to reduce, due to only 2–2.5 bar differential required for optimal performance)

-

Operation: Normally closed, cycling 30–40 times per day

-

Installation Orientation: Both vertical and horizontal pipework

The valves’ simple and robust design — consisting of a rubber sleeve compressed by air pressure to shut off the flow — provides an ideal solution for abrasive media.

Performance and Maintenance

The AKO Pinch Valves have demonstrated exceptional reliability and durability throughout their service at this plant.

-

Longevity: Many valves have been in service for decades with minimal issues.

-

Maintenance: Sleeve replacement is the most common maintenance task and is dependent on usage and the abrasiveness of the material handled. Over extended periods, flange wear may also occur but is easily manageable.

-

Efficiency: Recent review identified that 7 bar closing pressure was excessive, and that 3 bar is sufficient to achieve full closure (2 – 2.5 bar differential required), since only 1 bar line pressure is used. This adjustment will help reduce energy consumption and extend sleeve life.

Customer Feedback

The company’s maintenance and operations teams have expressed long-term satisfaction with the AKO Pinch Valves, citing their consistent performance and reliability:

“The AKO Pinch Valves do the job that is required – we’ve never had any issues with them. They’ve been part of our plant for over 26 years and continue to perform exceptionally well.”

— Plant Representative

Results

| Benefit | Description |

|---|---|

| Reliable Flow Control | Consistent and accurate opening/closing for powder transfer between silos and mixers. |

| Reduced Maintenance | Simple sleeve replacement process; minimal downtime. |

| Long Service Life | Proven durability over 26+ years of continuous use. |

| Energy Savings | Optimised air pressure (reduced from 7 bar to 3 bar) lowers energy usage and extends sleeve lifespan. |

| High Operator Satisfaction | No operational issues reported; strong end-user confidence in the product. |

Conclusion

This end users continued use of AKO UK Pinch Valves over more than two decades stands as a testament to the valves’ durability, efficiency, and suitability for handling abrasive cementitious materials. The simple yet robust design of AKO’s Pinch Valves ensures dependable performance, low maintenance, and cost-effective operation — all essential factors in Bostik’s high-volume, powder-handling environment.