A company that designs and manufactures high shear mixing equipment are using AKO’s stainless steel hygienic pinch valves to restrict and control the flow within their mixing range. The company were originally looking at wierless diaphragm valves because they needed initial full bore and minimum turbulance when closing. They then heard about AKO’s range of Pinch Valves which seemed the solution to their process.

The in-line mixing machines feature a unique and innovative pumping design which allows the mixer to achieve very high flow rates. A valve is required on this piece of equipment, to control the flow of the product passing through the pipelines, which in this case is xanthan gum.

Xanthan gum is widely used as a thickening and stabilising agent in foods, cosmetics, toiletries, pharmaceuticals and chemicals. It provides critical functionality to the end product, and dispersing it correctly is the key to a successful process. Although xanthan gum only makes up a small proportion of a formulation (anything from 0.1% – 2% of the end product), it is often prepared separately in higher concentrations.

The high sheer of this company’s mixers will rapidly disperse the xanthan gum, giving a uniform, lump free mix. The sheer mixing equipment is ideal for this application. it is ideal for high viscosity mixes, and will rapidly disperse and hydrate the gum.

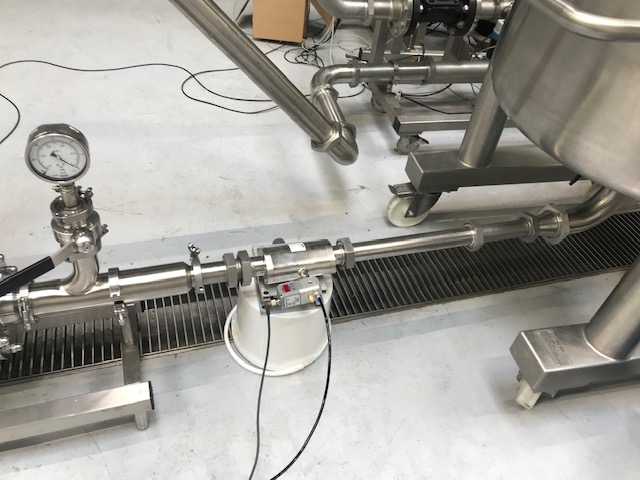

The mixers are hygienic in design, therefore a hygienic valve was required. The VMCE type Pinch Valve by AKO is suitable for handling high viscosity creams, gels, and slurries in the food, pharmaceutical, cosmetic and chemical industries.

Because of the mixers in the range being developed for food and pharmaceutical industries, tri-clamp/RJT connections were ideal. But they also needed gradual restriction of flow for the ambient temperature xanthan gum, with no face to face restrictions. This could easily be achieved with a manual valve, but they needed sanitary fittings, so the company opted for AKO’s 2″ VMCE type EHEDG certified Pinch Valve with the additional of a proportional control system. They chose the weld-on ends option for the pinch valve for xantham gum, to weld on their own RJT fittings.

Pinch Valve used within this application – VMCE50.04HTECE.50RA

VMCE hygienic model, air operated, stainless steel body, stainless steel weld-on ends, EPDM food safe rubber sleeve

Operation of the Valve for Xantham Gum

For this particular application, the bore of the pinch valve is initially required to be full. The company were using a simple recirculation loop utilising a 500l vessel, with a flow meter incorporated in the line. Water passes through the pinch valve for xantham gum at ambient temperature. When the mixer was running without the pinch valve and using solid 2″ pipework, they achieved a consistent flow rate. But when the part of the solid section was replaced with the pinch valve, the flow rate steadily decreased.

The flow rate when these mixers are in operation is fairly high, and for that reason the company use a vacuum gauge in the line. The vacuum pressure was causing the rubber sleeve inside the pinch valve to draw out, which in turn was causing the product flow rate to drop.

AKO advised the company to attach the vacuum to the inlet of the pinch valve so that the same amount of vacuum is pulling the rubber sleeve both ways, therefore equalising the pressure and the sleeve remains in its normal position.

This small tweak within the application has solved the issue, and the pinch valve for xantham gum continues to control the flow of media passing through it with the addition of a proportional control system. The company are now very happy with the set-up and are utilising AKO Pinch Valves in the design of other parts of their machinery and equipment.