Pinch Valves & Biomass Power

A renewable energy production company are using Pinch Valves from AKO’s VF range to suspend and release powdered limestone through their pipelines.

Biomass power is electricity generated using plant-based fuels. This can include wood pellets and wood chips, bioenergy crops or even agricultural and domestic waste. It’s renewable because we’re continually growing plants and trees for a variety of purposes, but these processes often create residues that aren’t needed. Such residues can be used as a low-carbon, renewable alternative to displace fossil fuels. We can also use purpose-grown crops.

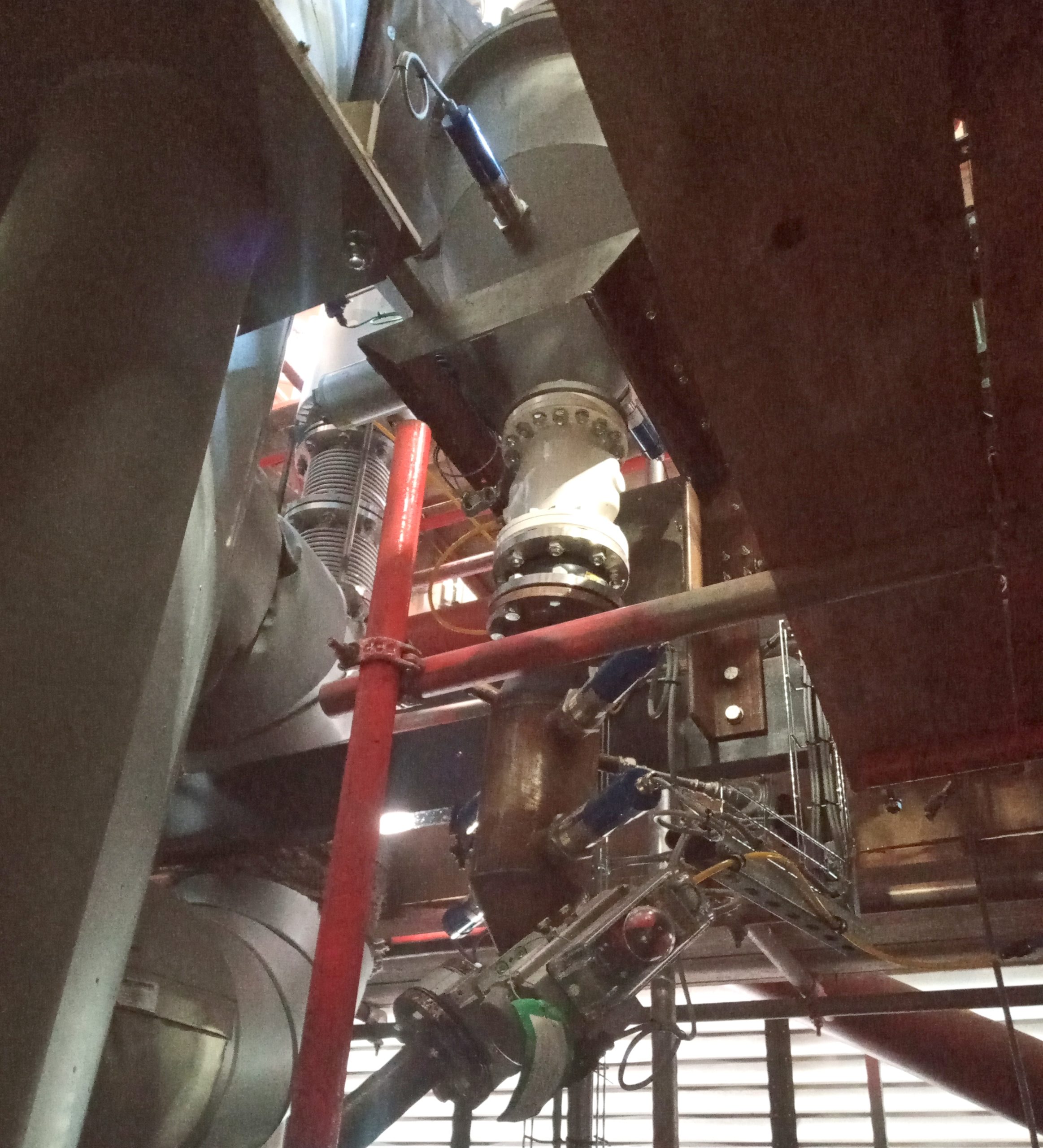

The Pinch Valves on this plant are installed in a vertical orientation, and held in the normally closed position beneath a feed hopper. The powdered limestone is gravity fed through the valve, at an ambient temperature. The flexible natural rubber sleeve inside the pinch valves has a strong elastic membrane, enabling it to fully shutoff any media with a leak tight seal. The rubber sleeve also opens to a 100% full and true bore. The elliptical shape of the pinch valve body ensures that the elastomer sleeve compresses in the same position every time that compressed air is applied. Furthermore, the valve bladder material is abrasion resistant, and can handle any aggressive media with ease.

Pinch Valve Performance

The pinch valve for powdered limestone opens and closes 7 times per day within this particular application. The energy production company have been using AKO pinch valves for just 1 year so far, and are yet to carry out a replacement of the internal rubber sleeve. The pinch valves have only been in sporadic service due to process issues with the plant.