By complying with EX standards, AKO UK provide Pinch Valves certified to an EX Conformity for use in areas with a potentially explosive atmosphere in industrial plants.

The AKO EX approved Pinch Valve is intended for use in potentially Explosive Zones 0/20, 1/21 or 2/22. The definition for each EX zone is based on the type of potentially explosive atmosphere (gas or dust), the probability that it will occur and the duration of its occurrence. Zones 0, 1 and 2 are for gas/air mixtures and zones 20, 21 and 22 are for dust/air mixtures.

Special precautions must be taken in the local environment (rooms, etc.) and within the plant (pipelines, valves, control units, etc.) depending on the defined zone.

Ex zone 0:

Potentially explosive gas/air mixtures can occur continuously or frequently over a long period of time in this zone.

Ex zone 1:

Potentially expolove gas/air mixtures can occur occasionally in normal operation in this zone.

Ex zone 2:

No potentially explosive gas/air mixtures will normally occut in this zone. However, potentially explosive atmospheres may occur for a short period of time in exceptional cases under certain circumstances in this zone.

Ex zone 20:

Potentially explosive dust/air clouds can occur frequently and for long periods of time in this zone.

Ex zone 21:

Potentially explosive dust/air clouds can occur occasionally under normal circumstances in this zone.

Ex zone 22

Potentially explosive dust/air clouds will not occur under normal conditions. However, they can occur very rarely for a limited amount of time in exceptional cases.

The Ex zone does not only cover areas where media that are prone to trigger an explosion due to their composition, such as chemical substances or gases, are processed but also covers areas where a large number of generally harmless media are processed that may nevertheless generate potentially explosive conditions. For example, dusts, vapours or gases could be generated during the transport or processing of these usually harmless substances that could combine with oxygen or air to generate an explosive mixture.

Pinch Valves Conduct Electrical Charge to Prevent Discharge in the Form of Sparks

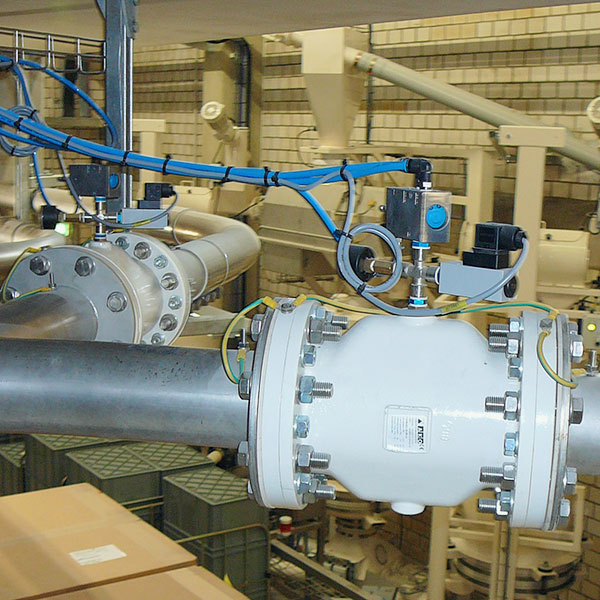

The EX Pinch Valve is physically very similar to a ‘standard’ Pinch Valve, keeping the main advantage of the completely clear bore and super fast shut off times. In fact the only visible differences are the lock teeth washers and the earth connection. The washers of the EX Pinch Valve are used with the flange bolts to give full contact with the aluminium body through the paint. This ensures if required, electrical current can pass safely though the Pinch Valve. The earth connection is located on one of the flanges or screwed ends of the valve.

The sleeves currently available for the AKO EX Pinch Valve are conductive Natural Rubber, EPDM, EPDM Food Quality (FDA Approved) and Nitrile. The sleeves have electrically conductive properties that prevent an explosion inside a pipeline system.