A toll blending company, whereby the production of (complex) chemical products is outsourced to a third party company (blender), blends cement and plaster products to the customers needs and packages the product into paper sacks, bulk bags and road tankers with the help of valves.

The valves for bulk filling are installed and positioned on a sack fill machine behind the spout to start and stop the filling operation. Pinch Valves are the type of valve used within the application, which assist by controlling the filling operation, and packaging the product into paper sacks.

Application Details

The cement/sand/plaster mix running through the Pinch Valves for bulk filling is ambient in temperature, and flows through at a positive pressure of 2 bar. With the Pinch Valves being normally closed, approximately 2000 cycles per day are performed.

When the filling operation is close to the target weight, 1-1.5 bar of pressure near the end of the bag filling operation is used to partly close the valve and slow down the filling to get an accurate bag end weight. To fully close the valve, around 4 bar is applied.

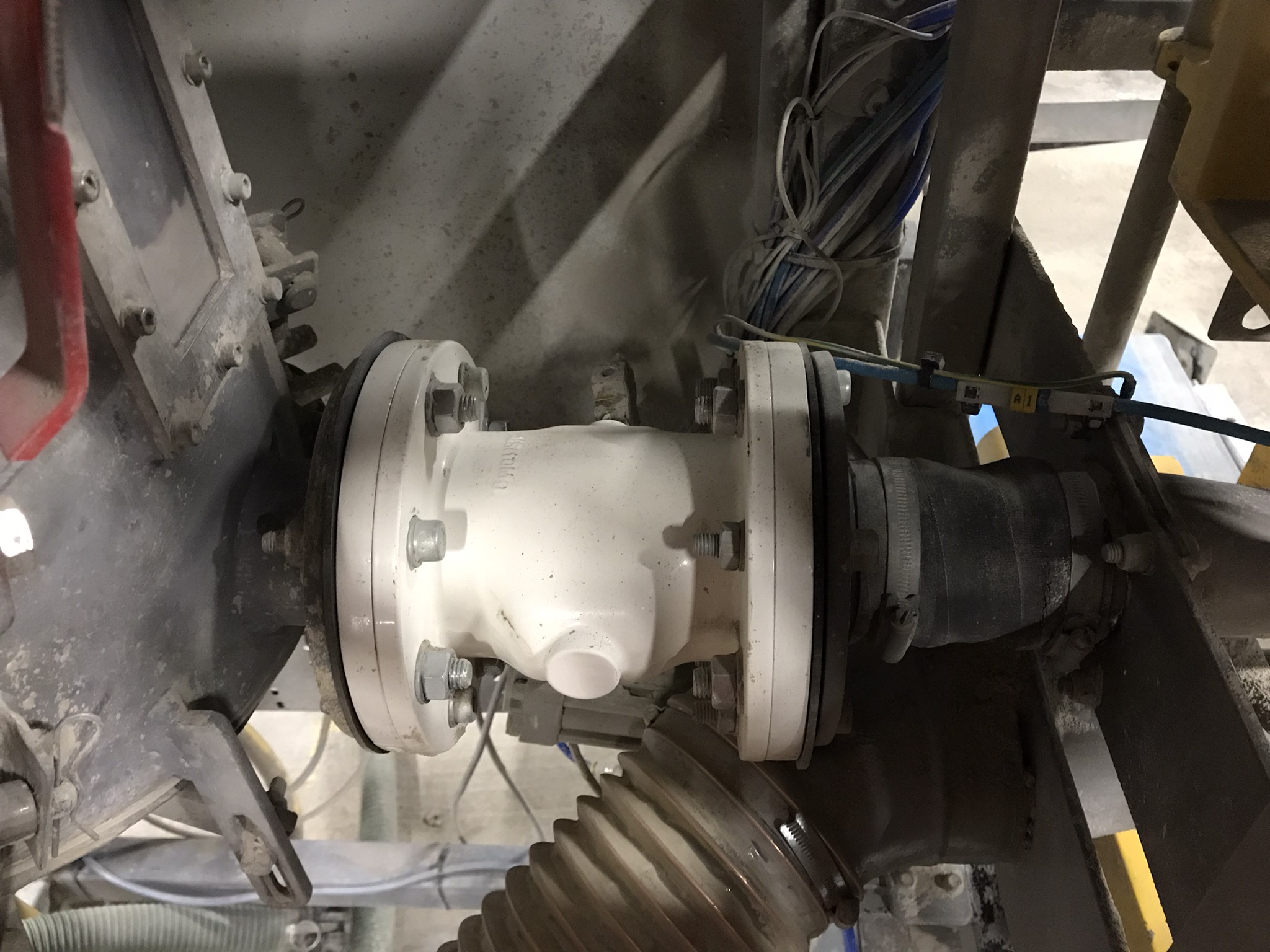

Pinch Valve used within this application: VF065.03X.31.30LA

VF model, air operated, aluminium body, aluminium flanges PN10/16 with mild steel bushing contact parts, natural rubber sleeve.

Valve for Bulk Filling User Benefits

The toll blender purchased a sack fill machine five years ago that was using AKO’s Pinch Valve, and they have continued to use the same valve as it performs well for the duty required. They use all type of valves, which the user told AKO UK all have their pros and cons for each individual application. But the user also said that the benefit they found from using AKO Pinch Valves for bulk filling was the zero restriction you get for product flow and the ability to use different pressure to control the flow of material, plus the very compact and light design.

The user further explained that they are very impressed with the AKO Pinch Valve:

“We have some renovation on our existing plant coming up and will no doubt be using pinch valves to improve the old butterfly valves we currently use.”

The toll blending company have only replaced the sleeve once in the 5 years of operation. The plant it is used on is roughly used 3 times a week, around 2000 cycles per day.

The pressure is applied using a regulated air supply to an air solenoid controlled by weigh scales, to apply and remove the air at set weights. It is opened quickly using a quick exhaust valve to remove the air when the pressure is removed for fast operation.

The user confirmed that they will be updating their outdated plant and will be using pinch valves for bulk filling in the same way to update their old sack fill machines.