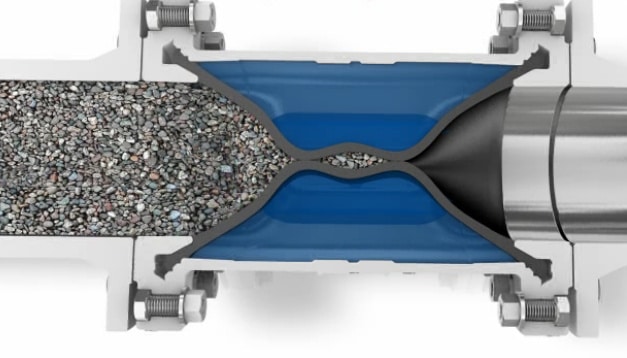

Valves for Sand Applications

Pinch valves are known to be the most versatile valves that are capable of handling rough and highly abrasive flow media, such as sand, cement, silica, and slurries. Pinch valves for sand control are commonly used in sand blasting machines and sand transfer lines. They feature a full-port opening, ensuring maximum flow of both dry and wet sand.