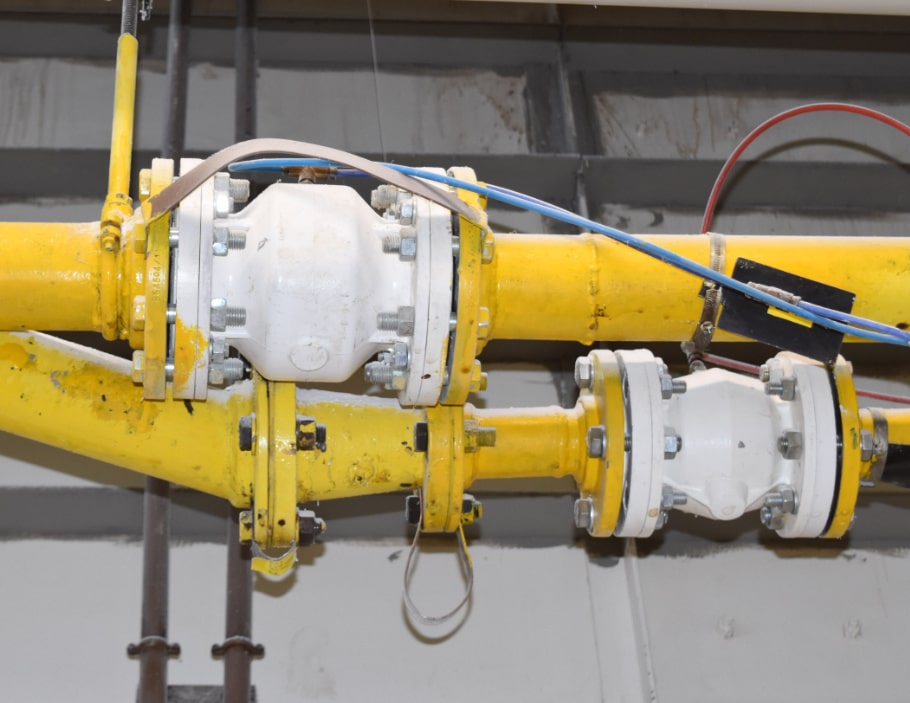

AKO VMP Type Plastic Pinch Valve used in Printing Company

AKO’s Pinch Valve range covers a diverse selection of sizes, body materials, end connections and internal rubber sleeve materials. This gives the user a huge advantage over other valve types on the market because the AKO Pinch Valve will be suitable for almost every application.