The Materials & Temperatures of A Rubber Membrane in Valves

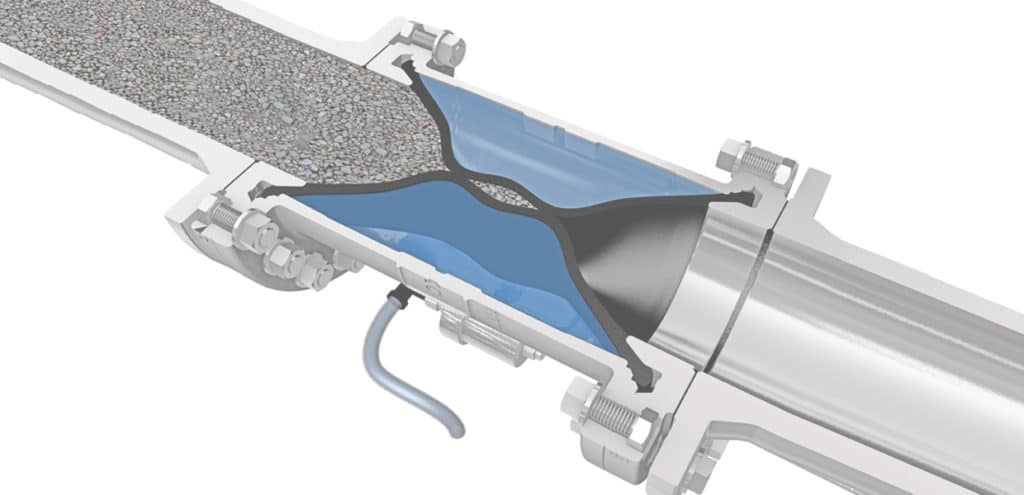

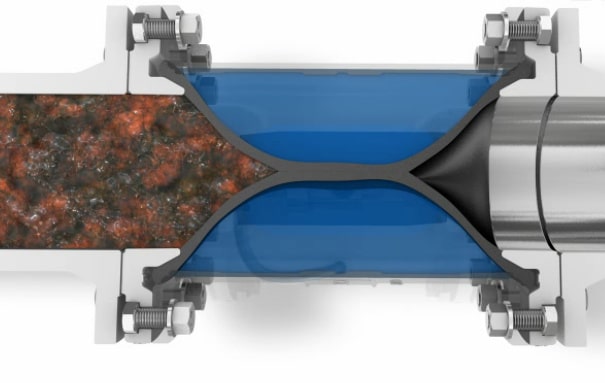

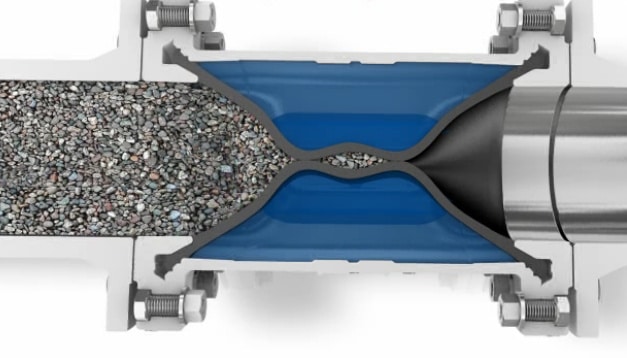

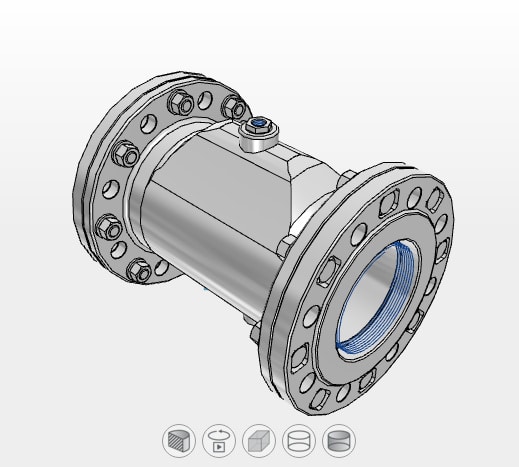

The rubber membrane liners of the air operated pinch valves are usually press-fitted and centered into the housing ends by the socket end covers or flange.

A rubber membrane may also be known or nicknamed as a Hose, Bladder, Membrane, Seal, Seat, Tube, or Sleeve.