The Process of Milling Flour

The flour milling process has evolved from wheat being ground between two large stone wheels (although this process does still occur in a few mills). In a roller mill the practice centres around separating the three components of a wheat seed – the white endosperm, the outer bran layers and the wheat germ. These are each made up of different materials and when separated and milled in isolation the miller can produce flours that are finer and therefore better suited for today’s uses.

A local flour milling company is responsible for it’s group’s biggest flour output – over 200,000 tons of wheat is milled annually, resulting in 150,000 tons of flour. This is mainly for bread production, but is also for biscuit manufacturers and other specialist areas.

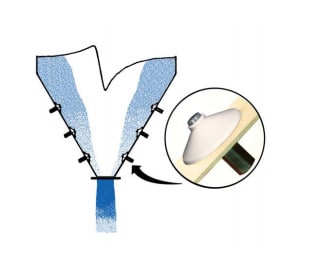

The transportation of flour around the mill and into the desired bins and packing bags is an important task, one of which is controlled using valves.