Industrial Food Technology System

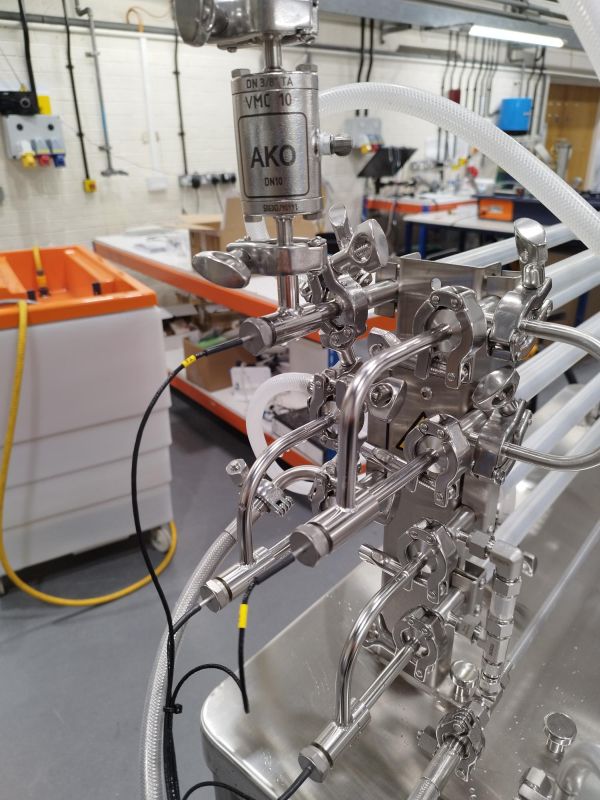

An Original Equipment Manufacturer providing R&D equipment to the food industry have provided a pneumatic Pinch Valve from AKO UK onto one of their flexible, miniature-scale processing systems which makes it ideal for new liquid food product development. The pinch valve replaces the standard sprung backpressure valve when processing with particulate-containing products, and requires a compressed air supply to operate.

The system has an integral pressurised hot water generator and requires only electricity and cooling water to operate. A progressive cavity feed pump ensures that flow rates are independent of viscosity/backpressure changes and allow a maximum operating pressure of 10 bar.

Some of the liquid food media with suspended solids that this system handles are: