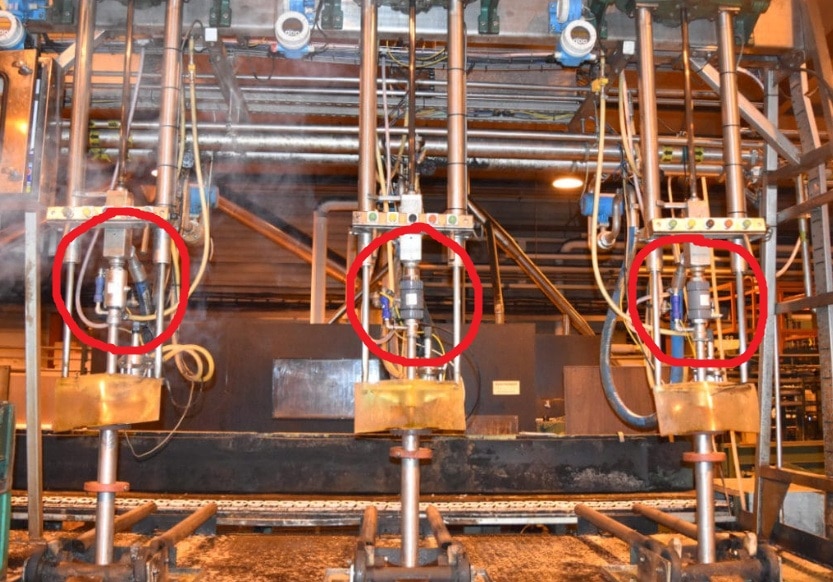

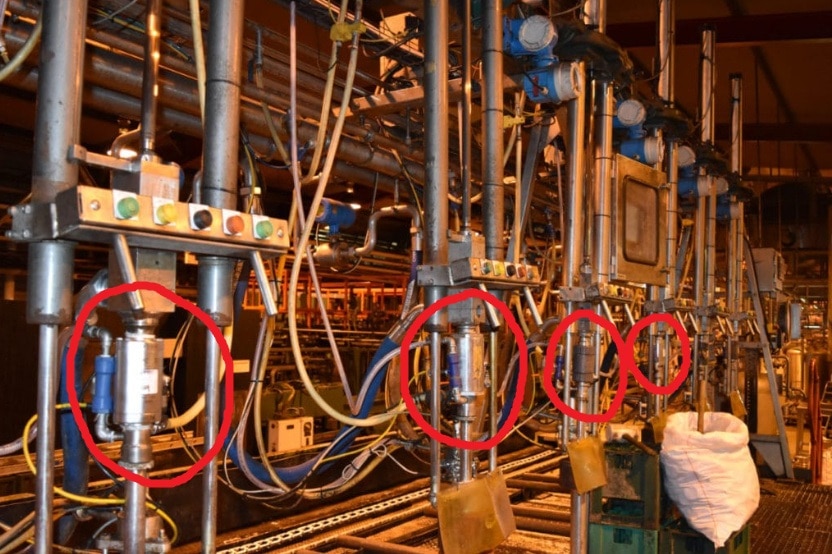

A brewery producing fine ales are using AKO Pinch Valves in their hygienic system. The brewery have been using AKO Pinch Valves for 10 years so far, after switching from an alternative pinch valve manufacturer because the previous brand was not so reliable.

The brewery started off using the PVC bodied Pinch Valve product code VM032-02X-50-80. These valves were then replaced with the newer improved VMC type Pinch Valve in complete stainless steel, product code VMC32-02X-50G-50. This stainless steel version have currently been installed for 5 years without needing to be replaced.