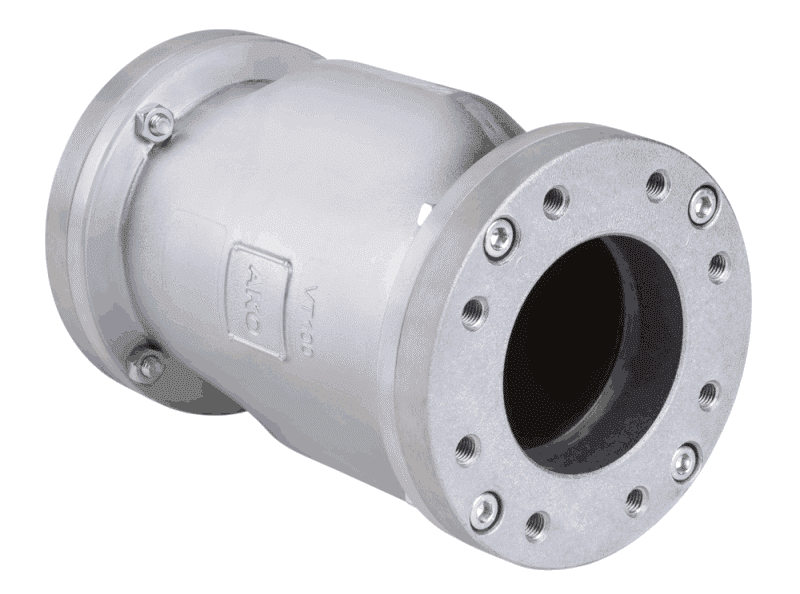

Stainless Steel Sterile Valves are used in Aseptic & Pharmaceutical Applications

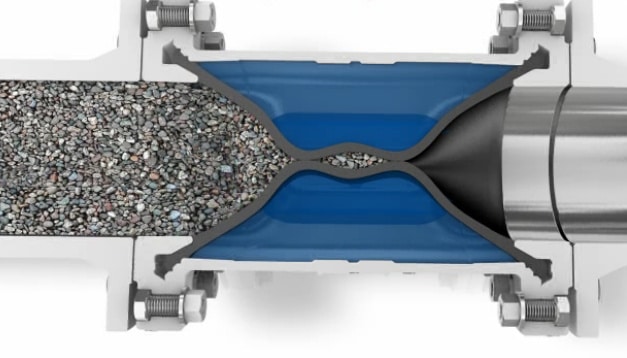

Sanitary or sterile valves are one of the best choices for applications where sterility, cleanliness, zero dead volume, and uninterrupted flow are of utmost importance. The rubber tubing inside the sterile valves provides an unobstructed flow path that drastically reduces shear effect and turbulence of the media. This also results in minimal loss in pressure, which further improves the efficiency of the system. The flowing media also stays inside the original supply tube.