Aggregates are a popular media type in the building and construction industry, and consist of different sized, usually hard particles or pieces of material including gravel, sand, recycled concrete, slag, topsoil, ballast, Type 1 MOT, and geosynthetic aggregates.

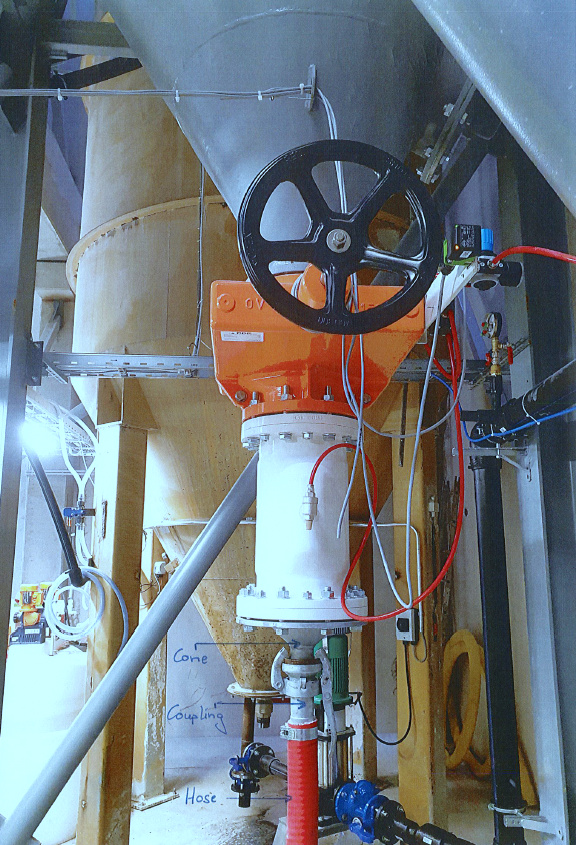

When travelling through silos, hoppers and pipework, these aggregates often need a valve to stop/start the flow process. Pinch Valves are the ideal valve type for this scenario, with their simple construction and straightforward performance.