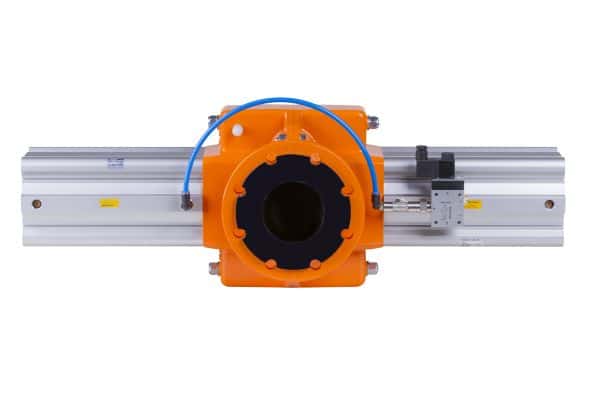

AKO Pinch Valves used in Robotic 3D Concrete Printing Application

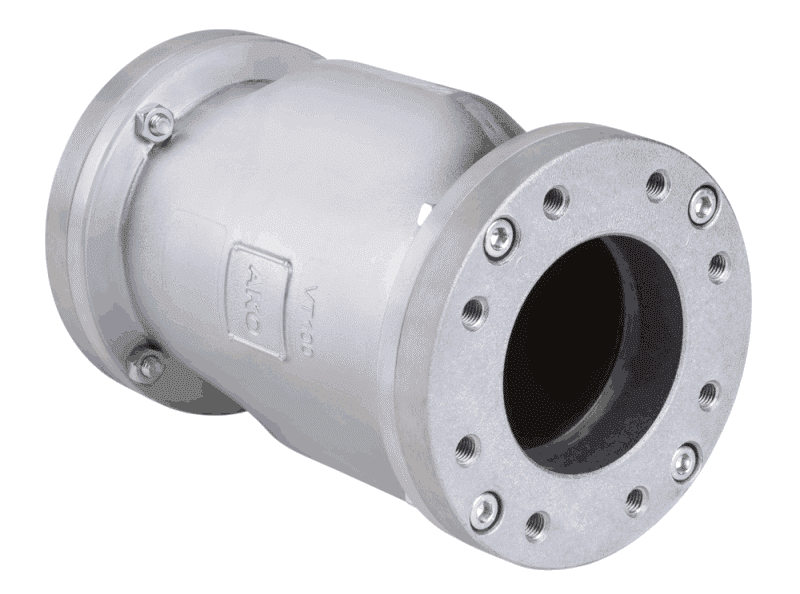

AKO UK are supplying their VMP plastic Pinch Valve in DN25 (product code VMP025-03XK-72) into a concrete slurry application, which is used as a fail safe option. The concrete slurry with very fine aggregates in size 0.3-1mm is used for robotic concrete printing.

The world’s first commercial 3D concrete printing robot is currently in design production, with the aim to be used on site to produce a variety of elements including cladding panels.