The production of various different synthetic products from a variety of raw materials is dealt with in the plastics industry. Plastics production is split into three types of plastics: thermoplastics, thermosetting polymers and elastomers. In each of the three branches, valves control the transportation of powders, granulates and fibres, by pneumatic conveying or gravity feeding, shutting off and suspending the media.

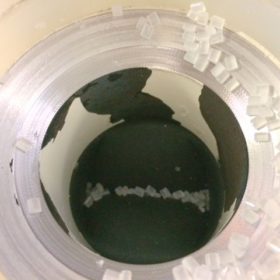

Whether the plastic substance is in powder form, pellets, caplets, granules, dust, pigments, fibre, filings or liquid, AKO Pinch Valves are the ideal flow control solution for handling and conveying this type of media in any plant.

Effortless Conveying with Pinch Valves

Some of the advantages and characteristics of AKO Pinch Valves include a tight seal, no blockages, and a full bore. All of which are important factors for an effortless free flowing system where the engineer does not need to worry about breakdowns or problems with the valve clogging etc.

Sack or bag filling is another application area where raw plastic materials in bulk are handled with ease by pinch valves. The simple and fast on/off function of the pinch valve enables an efficient product delivery and suspension.

Typical Plastic Substances Handled by Pinch Valves

- Carbon Black

- Dicalite

- HDPE Powder

- Epoxy Resin

- Polystyrene or Styrofoam

- Latex

- Irgafos 168

- LLDPE

- Mica

- Thermoplastics

- Polymers & Elastomers

- Nylon Beads

- Polyethylene

- PVC Dust

- Silica

- Polyvinyl Chloride

- Polypropelene

- Silicon