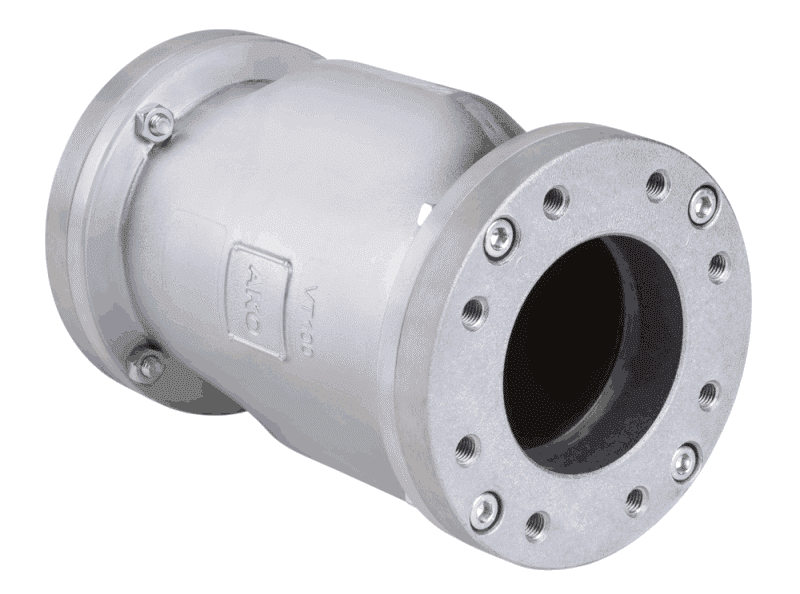

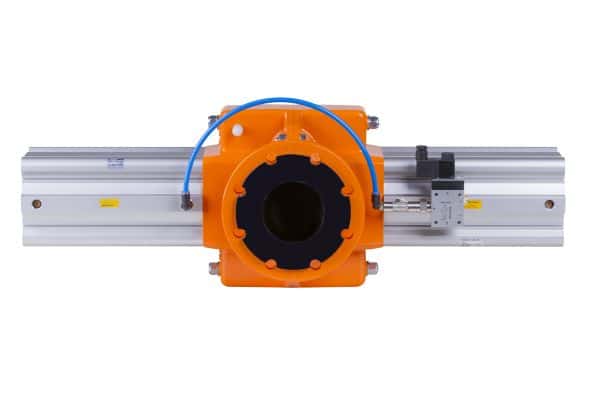

Low Maintenance Valves are key to Industrial Applications

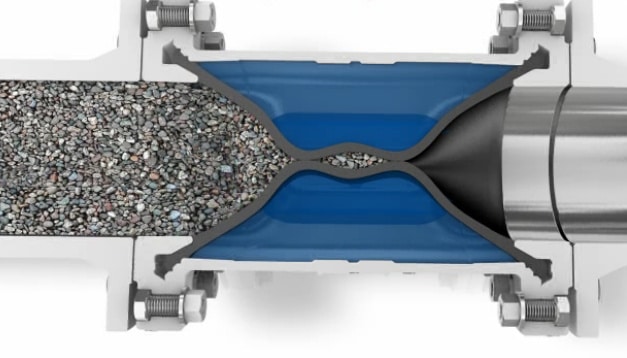

One of the highlighting features of the pinch valve is that it requires little to no maintenance. This is because the only part that undergoes wear and interacts with the flowing media is the rubber sleeve. The component is made of a highly corrosion and abrasion resistant material, such as rubber, silicone, and several other forms of elastomers, which dramatically increases the wear-life of the sleeve in these maintenance free valves.