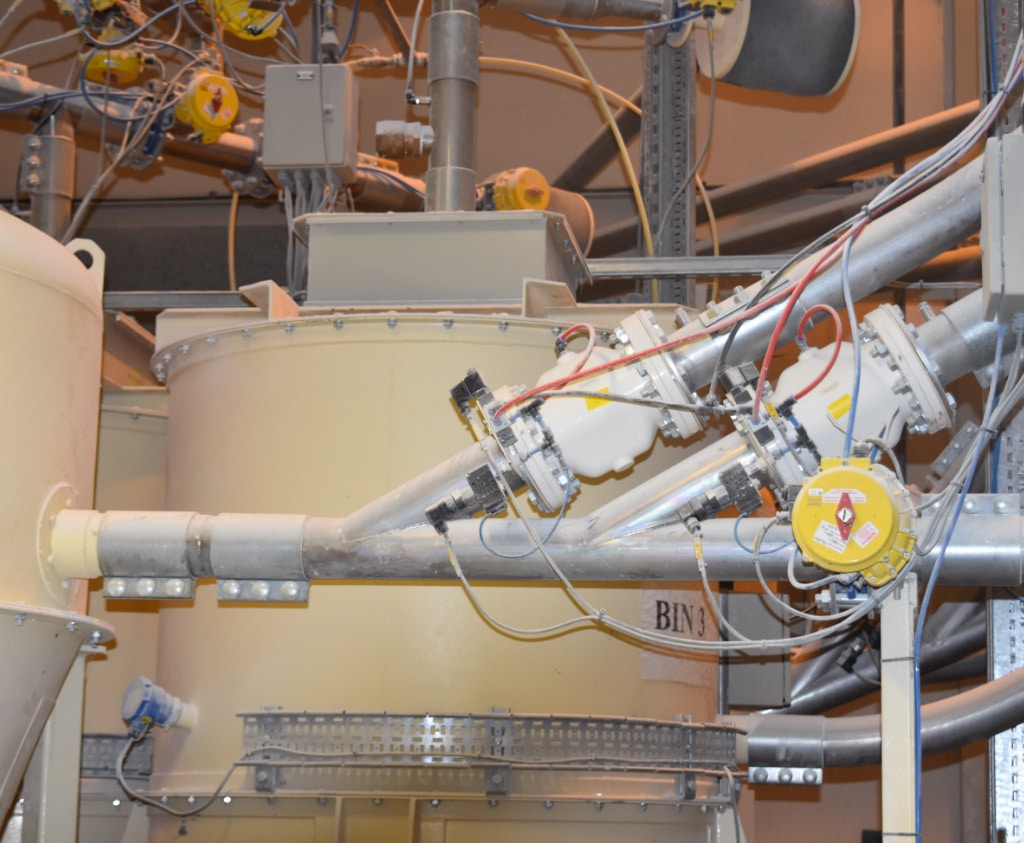

Many different abrasive powders for the ceramics industry are being produced more often. These ceramic powders and glaze materials travel around pipelines in bulk conveying systems in many valve and aerator pad applications. The powders are transported from silos/hoppers/bins onto trucks, and also weighed and bagged with sack filling machinery. The increase in powder processes means the demand for reliable valves to transport and shut off the raw materials is higher.

The Pinch Valve replaces many ball valves and butterfly valves that were originally installed in these powder applications, where clogging occurred. Powders and ceramic material do not become blocked or clogged with a pinch valve – The soft internal rubber sleeve opens and closes in the same position every time, loosening any crustations that fall back into the product flow. This full bore opening of the pinch valve allows a free flowing product.

Pinch Valve Characteristics

The powders being passed through the fully open bore of a Pinch Valve can either be gravity fed, pushed along using compressed air, or sucked through using a vacuum system. Whichever conveying method is used, Pinch Valves guarantee a free flow of product because of the nominal passage of practically all diameters. The Pinch Valve is a reliable valve option, and in most cases wear resistant. Other advantages include it’s light weight, tight shut off, simple installation and lightening fast opening/closing times.

Even after long periods of time being in contact with some of the most abrasive powders and raw ceramic materials for many cycles, the Pinch Valve continues to prove it’s worth.

Examples of Powders Processed using Pinch Valves

- Aluminium Oxide

- Barium

- Bentonite

- Calamite

- Calcined Kaolin Clay

- Calcium Carbide

- Calcium Carbonate

- China Clay

- Kaolin mining

- Cordierite

- Cobolt

- Dolomite

- Flint

- Soda Ash

- Iron Oxide

- Kiln Dust

- Lead Oxide

- Lithium Carbonate

- Silicon Carbide

- Fluxes & Additives

- Manganese Dioxide

- Magnesium Oxide

- Nickel Oxide

- Potash

- Feldspar

- Potassium

- Sodium Carbonate

- Zinc Oxide

- Zirconium oxide